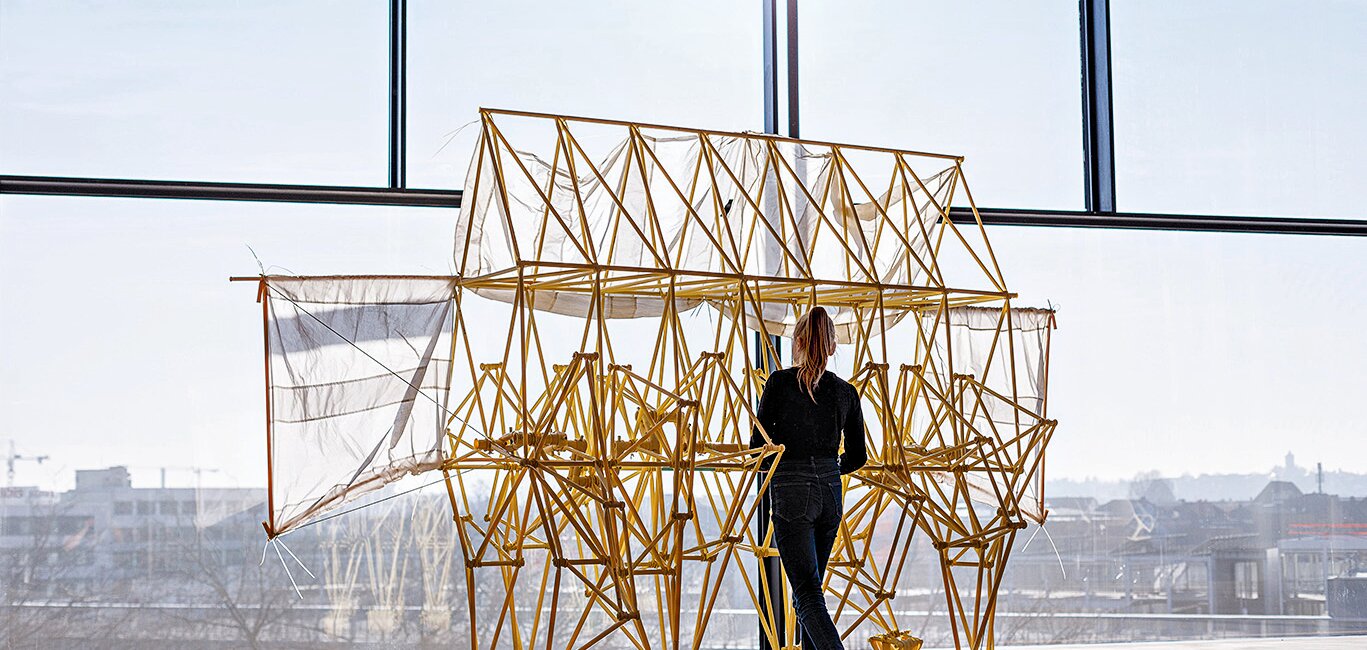

Located in the north-west of Heilbronn city centre, the spectacular new experimenta building has quickly become a new landmark for the city. The sensational glass and steel building is particularly impressive after dark. The new building, which was completed in 2019, owes its unusual architectural appearance to the staggered storeys and sophisticated design of the façade.

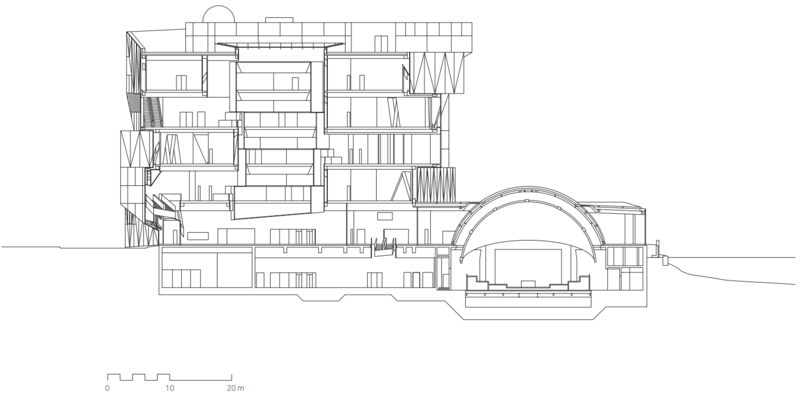

The individual floors of the experimenta can be explored via the dynamic structure of the visually dominant spiral of rooms. If you walk up all five floors from the foyer to the landscaped roof terrace, you will experience constantly changing insights and views. Once on the roof, visitors can also enjoy an impressive view over the Neckar valley.

Such diversity results from the materials used in the construction of the façade - glass and steel - and the special printing of the façade, in which transparent and opaque elements alternate repeatedly. One of the customer specifications during the planning of the experimenta extension was the desire for high sustainability standards during construction. With a double, congruent digital dot printing of the façade's glass, it was possible to achieve some of these standards. It significantly reduces the heating and cooling load in the building, making the use of movable sun shading devices completely unnecessary.

The overall sustainable design of the new experimenta building was honoured with the DGNB Diamond Award from the German Sustainable Building Council. This makes experimenta the first building to receive this award in the ‘Museums’ category.

The client of experimenta is Schwarz Real Estate GmbH, a sister company of Dieter Schwarz Stiftung GmbH, which is committed to promoting education and science under the banner "Promoting education, sharing knowledge, daring the future". Back in November 2009, the foundation, together with other sponsors, made it possible to open the existing experimenta Science Centre building, which was created from the former Hagenbuch oilseed storage facility.

Visitors were able to discover and better understand science and technology in an area of 7,500 square metres at the time. The former experimenta was closed in the summer of 2017 in order to construct the spectacular extension and remodel the existing building of the former Hagenbucher Speicher. The two buildings were also to be connected by an underground tunnel. By the time it closed, 1.3 million visitors, mainly children, young people and families, had already visited experimenta.

With its diverse range of offers, experimenta is a unique world of knowledge and experience in which visitors become discoverers themselves. The Ministry of Culture, Youth and Sport of the state of Baden-Württemberg has even officially approved experimenta as an extracurricular place of learning and an extracurricular research centre.

Today, experimenta is GERMANY'S LARGEST SCIENCE CENTRE with a usable area of 25,000 square metres.

Long-standing D+H service and sales partner Hübler Sicherheit und Service GmbH supplied the right solution for smoke and heat exhaust ventilation on behalf of façade specialist Rupert App GmbH + Co. In 2020, experimenta's elaborate façade construction project even won an award: The family-run company App won the German Metal Construction Award 2020 in the "Windows, façades, conservatories" category.

The result of the intensive collaboration in Heilbronn was a customised smoke and heat extraction solution with 16 triangular backflow openings that blend harmoniously into the extraordinary architecture of experimenta. The particularly powerful yet stylish chain drives from the CDP series are perfect for the job. They move and hold the 4.6 metre high, 1.5 tonne windows, which are each supported by only four hinges, with absolute safety at all times.

VLD lock drives integrated into the window profile, with bracket sets and carriers specially designed for this use, ensure that all window sashes are firmly closed during normal operation. Even the highest architectural demands can be met with the CDP series chain drives. The drives surprise with their stylish, slimline appearance and yet are among the most powerful chain drives on the market. This makes them ideal for particularly large, heavy façade or roof windows.

The façade of the new experimenta building is particularly unusual when it comes to fire protection. The complex design by Berlin architects Sauerbruch Hutton envisaged interlocking triangles for the design of the individual fronts. Some of these triangles are used as smoke and heat exhaust ventilation panels that can be opened automatically in the event of a fire.

The perfect realisation of individual solutions

The dimensions of the storeys alone - and therefore also those of the triangles - mean that the trapezoidal window sashes required are around four metres high. In order to move a geometric shape made of glass and steel with these dimensions and a corresponding weight reliably and automatically, a powerful, customisable system solution for smoke and heat exhaust ventilation is required.

Hübler Sicherheit und Service GmbH has developed the ideal solution here in close cooperation with the façade builder App. Special architecture? Special solutions!

D+H partner companies such as Hübler are characterised by their special proximity and good, established relationships with their customers. These personal relationships are the foundation of the D+H Group's success. Especially when it comes to identifying and installing the right products for an optimised smoke and heat extraction solution.

The technicians and engineers in the D+H Group's technical sales department are also very familiar with the needs of processors during the tendering phase. They are also available at any time after a tender has been won. With a great deal of routine, the experts ensure that even complex architectural designs - often with high technical demands - are harmonised with the requirements for standard-compliant smoke and heat exhaust ventilation.

The result of the intensive collaboration in Heilbronn was a customised smoke and heat extraction solution with 16 triangular backflow openings that blend harmoniously into the extraordinary architecture of experimenta.

Tested safety under the magnifying glass: SHEV conformity in Germany's largest science centre

When it comes to safe escape routes for hundreds of people, as is the case at experimenta, the appropriate smoke and heat exhaust ventilation must be guaranteed. Standards must be met for this.

In buildings with a high level of public traffic, comprehensive legal specifications must be observed with regard to fire protection. Accordingly, an optimised fire protection concept must be developed for such buildings in particular. If, for example, rooms are planned in Germany that can accommodate more than 200 people individually or in total, the German Venue Ordinance, which defines the requirements for smoke exhaust, must be implemented. As a sub-aspect of fire protection, smoke and heat exhaust systems are subject to the building regulations of the respective nation.

In the event of a fire, natural smoke and heat exhaust ventilators usually discharge hot smoke gases via an aerodynamically effective smoke extraction surface. This ensures smoke-free areas near the floor and in escape routes. The main components of a smoke extraction system require safety certificates. For each construction product of this attachment, proof must therefore be provided to a notified body that it meets the requirements of certain performance classes of the respective European harmonised test standard of the EN 12101 series of standards.

The requirements are regulated within Europe depending on the country, building use and in accordance with the applicable EN 12101-1 to 12101-10 series of standards. However, due to a lack of local standards, the customer specifications of the EN standard are used in many places around the world - in some cases also as an ISO standard.

No natural smoke extraction system was possible in the new experimenta building. A mechanical smoke and heat exhaust system with supply air openings automated by D+H products ensures safety in the exhibition rooms.

In case of a fire, smoke and heat are drawn out of the building by smoke extraction fans. At the same time, a comparable amount of fresh air flows in through the large, triangular openings. Whether natural or mechanical, the normative requirements for smoke extraction systems for complex buildings are usually very comprehensive and vary from country to country. However, you can benefit from the technical expertise of D+H and its partners, especially when it comes to these stringent requirements.

As Chairman of ISO/TC 21/SC 11, Maik Schmees, CTO of D+H Mechatronic AG, is the expert for standards relating to smoke and heat exhaust ventilation from buildings.

"We have managed well over 50 projects together."

Façade builder Rupert App GmbH & Co. was also involved in the construction of experimenta together with Hübler Sicherheit und Service GmbH and D+H. In this interview, Bernd Einsiedler, Project Manager at Rupert App, talks about hurdles, perseverance and awards.

Congratulations, Mr Einsiedler! You recently won the German Metal Construction Award 2020 with the façade of the experimenta in Heilbronn.

"Yes, that's right - and that makes us a little proud. But our team and our partners also worked really well together in Heilbronn. In the end, everything just fell into place."

"Backflow openings for the mechanical smoke vent in the building had to be created in the surrounding room spiral. Due to the given structure of our façade, we had to plan a total of 16 opening sashes in eight triangles standing on their apex. We are talking about sash dimensions of around 2.5 metres wide and around 4.6 metres high, with a sash weight of almost 1.5 tonnes."

"Absolutely! After countless tests, together with the Hübler company, we have found a perfect drive and locking solution for the reinforced window profile frames of Forster Profilsysteme AG from Arbon in Switzerland. In fact, we have succeeded in moving these mighty opening sashes with just one D+H chain drive from the CDP series and keeping them securely closed with just two D+H lock drives each."

"The geometry, the size and the associated sash weight were real sticking points during the planning stage. But everyone also had to take a very close look during production to ensure compliance with the very tight tolerances when installing the drives on the reinforced profile frames. Standard fastenings were not feasible for this project and the carriers for the lock drives had to be completely redesigned. Otherwise, it would not have been possible to close these enormous triangular sashes cleanly and safely using automation."

"We have been relying on the specialists from the D+H Group for decades. When it comes to façade projects with complex opening elements for smoke and heat exhaust ventilation, we know who to turn to. In Heilbronn, Thomas Klaus from Hübler, Ronald Schwan and Dimitrij Moor from D+H were once again our trusted experts."

"Our strength is the realisation of special solutions."

Thomas Klaus, Sales Manager at the Ulm office of long-term D+H partner Hübler Sicherheit und Service GmbH

Drees & Sommer AG, the General Construction Manager and DGNB auditor at experimenta, was more than convinced by this jointly developed solution during the commissioning of the SHEV system and commissioned D+H partner Hübler with the maintenance of the drives and trapezoidal windows.